Introduction

Introduction

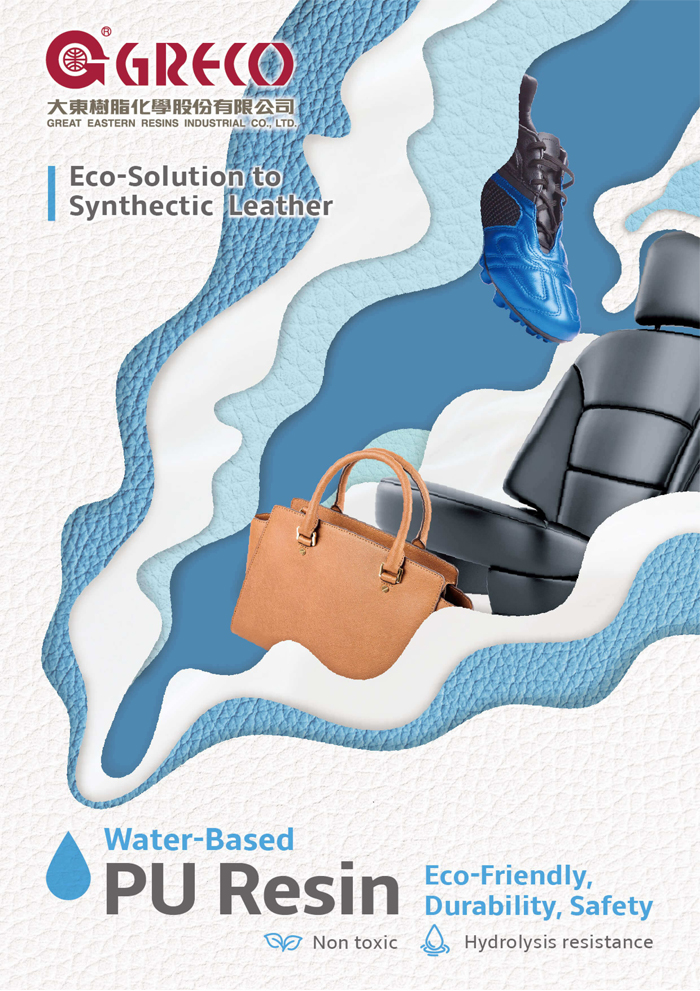

Eco-Friendly,Durability,Safety

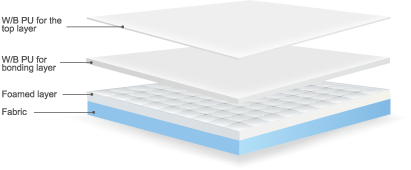

GRECO provides water-based PU for both top and bonding layers which is a great solution to convert solvent based into solvent-free process. It can be used for sports shoes,sports goods,surface coating of safety toys, automotive,as well as sofa leathers.

W/B PU for the top layer

High-strength grades

High mechanical strength, good hydrolysis resistance and easy-to-use

*Suitable for sports shoes, sports good

Weather-resistance grades

High durability, good wear resistant and easy-to-use. Suitable for wet-process .

*Suitable for automotive leather, sofa, and luggage

W/B PU for bonding layer

Wet process type

Excellent hydrolysis resistance, good resistance to strong alkali soaking, softness.

*Applicable to breathable materials(non-woven, woven, and micro fabric)

Dry process type

Capable for heat press process, high bonding strength, and easy to use good hydrolysis resistance, meets NIKE G-57 standard.

*combination of TPU film and top layer

Packing

| Application | Item No. | Part | Process | Jungle Test

(weeks) | Peel strength

(kg/cm) | Bally flex

(RT) | NaOH 10%

(NIKE G57) | Solid contant

(%) | Remarks |

|---|

| Sports shoes |

SL-501T |

Top layer |

Roll coating |

3~4 |

>5 |

>100000 |

>24HR |

~45% |

|

| SL-501A |

Bond layer |

Roll coating |

2~3 |

>5 |

>100000 |

|

48~50% |

Dry and wet process |

Top coat for

toys ball |

6801 |

Top layer |

Spray |

3~4 |

|

|

>24HR |

~45% |

|

Automotive

leather |

SL-590T |

Top layer |

Roll coating |

8~10 |

>2 |

>100000 |

>72HR |

~45% |

*High temperature resistance:500 hrs at 120℃

*Rubbing Test(JIS 6404-6)with 1Kg: >10000

*Toyota abrasion test: >6000 |

| SL-590A |

Bond layer |

Roll coating |

8~10 |

>2 |

>100000 |

|

~50% |

Wet lamination |

| Sofa leather |

SL-561T |

Top layer |

Roll coating |

6~8 |

>2 |

>100000 |

>24HR |

~45% |

|

| SL-561A |

Bond layer |

Roll coating |

6~8 |

>2 |

>100000 |

|

~50% |

Wet lamination |

Contact: 王水南 Water 04-23587676 ext:650

E-mail : sales5@greco.com.tw / water@greco.com.tw