(Image Source: Canva)

There is a continuous transformation in the raw materials and industrial adhesives industry based on demands of manufacturers and the environmental sustainability. Due to many reasons, manufacturers seek for lightweight, high quality, environmentally friendly raw materials and adhesives. In this term, GRECO (Great Eastern Resins Industrial) comes on the stage with its TPU, LFRT, and water based adhesives.

GRECO is an innovative and contemporary raw material and adhesives manufacturer, following the requirements for the industry and transforms itself to provide sustainable solutions for the buyers’ demands. GRECO started its business life in 1955 as a shoe adhesives manufacturer. Since the beginning, the company has been investing on R&D to provide raw materials that meet buyer needs and industry standards best. Today, GRECO is one of the outstanding eco-friendly suppliers for TPU, LFRT, water based adhesives, specialty chemicals, and dry film photoresist.

This time we will focus on TPU/E-TPU and LFRT. Let us mention what is TPU/E-TPU, what is LFRT, fields of use, and GRECO’s solutions for these two types of advantageous materials.

TPU and E-TPU as an Eco-friendly Solution

TPU refers to thermoplastic polyurethane, which is a type of polyurethane with the characteristics of elasticity, recyclability, transparency, and oil resistance. TPU is a healthy substitute for PVC and natural rubber, and can be the raw material of many different products related to shoes, sports and outdoor, yarn and clothes, water bags, frames, bike tires and many more. Only by using TPU, it is possible to manufacture an entire shoe. TPU is also a healthy material for the medical appliances, few of them can be sorted as medical tubes, varices socks, medical clothing and medical blankets.

GRECO’s ISOTHANE TPU has a rigidity level between 55A to 85D, which allows the manufacturer to produce soft materials such as phone covers to hard materials such as football shoes. This makes the company one of the most demanded suppliers for TPU products.

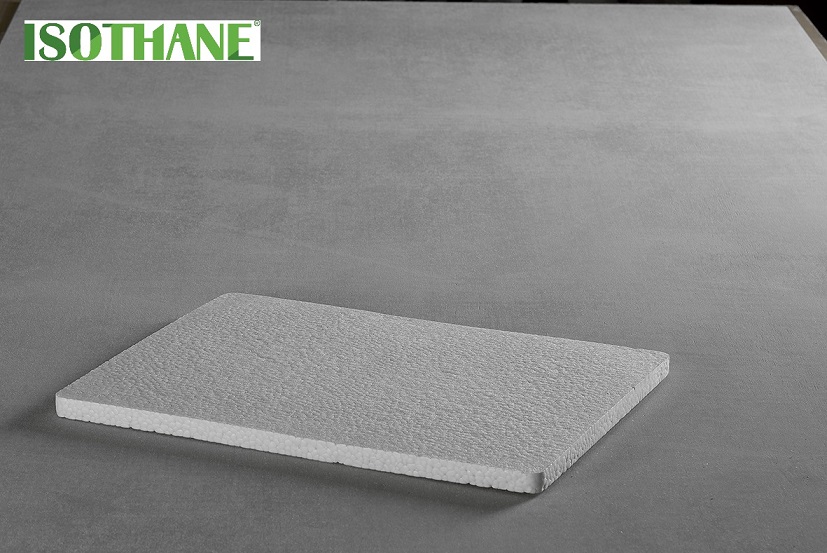

ISOTHANE E-TPU or Expanded TPU (Expanded thermoplastic polyurethane), is a foam version of TPU materials. Most characteristic feature of E-TPU is the low density and high elasticity up to -25°C. GRECO is able to manufacture E-TPU foam beads in different sizes and colors. That allows the users to have a wide range of customization on their final products. Some of the applications of expanded TPU can be listed as follows: Toys, helmet cushioning, packaging applications, bicycle tires, bicycle seats, and any application that requires flexibility.

In the era of environmentally awareness, many countries and companies focus on the philosophy of 4R of recycling (Refuse, reuse, reduce and recycle). One of the main reasons GRECO expanded its business to manufacturing thermoplastic polyurethane, TPU is helping to reduce carbon footprint and providing manufacturers eco-friendly solutions. TPE and E-TPU are suitable materials to recycle and reuse many times compared with PVC and rubbers. Moreover, it is a less harmful material to the environment, and can be disposed only within a few years underground.

(ISOTHANE ETPU Foam Beads)

“As an adhesive provider, there are three main objectives at present regarding the reform in the footwear sector,” said Ken Ho – the business director. “ The first is to continue developing water-based product package, secondly to introduce adhesive that is suitable for automatic production line, and thirdly to focus on energy saving and simplify shoe making process. These three goals highlight the trend of future shoe making adhesives development.

(ISOPAK Long-fiber-reinforced thermoplastic)

We also have the articles posted on PRM-TAIWAN, please check the link for more related information!

GRECO on PRM-TAIWAN B2B Platformhttps://www.prm-taiwan.com/com/GRECO.html