On the wide expressway, dazzling cars run fast; on the blue sea, elegant ferries sail steadily; well-known international brands, such as smartphones, sports shoes, Internet and digital technology industries, and even heavy industries that were originally carbon-emitting , have begun to think about how to reduce carbon, use digital transformation, green power energy, green process or renewable energy and recyclable materials.

More and more multinational companies, in addition to setting the goal of net zero carbon emissions, require supply chain cooperation in terms of design, manufacturing, and recycling, providing green power procurement ratios, or providing zero-carbon products and other supporting facilities.

It is obvious that ESG has become an indicator to measure the sustainability of a company.

In this wave of carbon reduction, the entire supply chain is changing. Are we ready to respond?

For the plastics industry, from the perspective of the raw material side of the supply chain, the green process can start with the use of environmentally friendly materials, biomass materials, and recyclable materials. GRECO has been deeply involved in green technology for a long time, starting from the Eco-friendly water-based adhesive for shoes, the Eco-friendly ISOTHANE TPU resin, and has also developed many special specifications with high added value, such as non-yellowing Aliphatic TPU, Bio TPU, lightweight long fiber Reinforced composite materials(LFRT), etc., these are green products that are easy to recycle.

The performance of these environmentally friendly materials, with the advancement of technology, has become more and more stable, and can gradually replace traditional PVC and other plastic materials that are not easy to recycle.

From the application side, in the automotive industry-Recently, TPU film has also been applied to a relatively high-end field, that is, the invisible car jacket industry.

Invisible car jacket is also called car paint protective film.

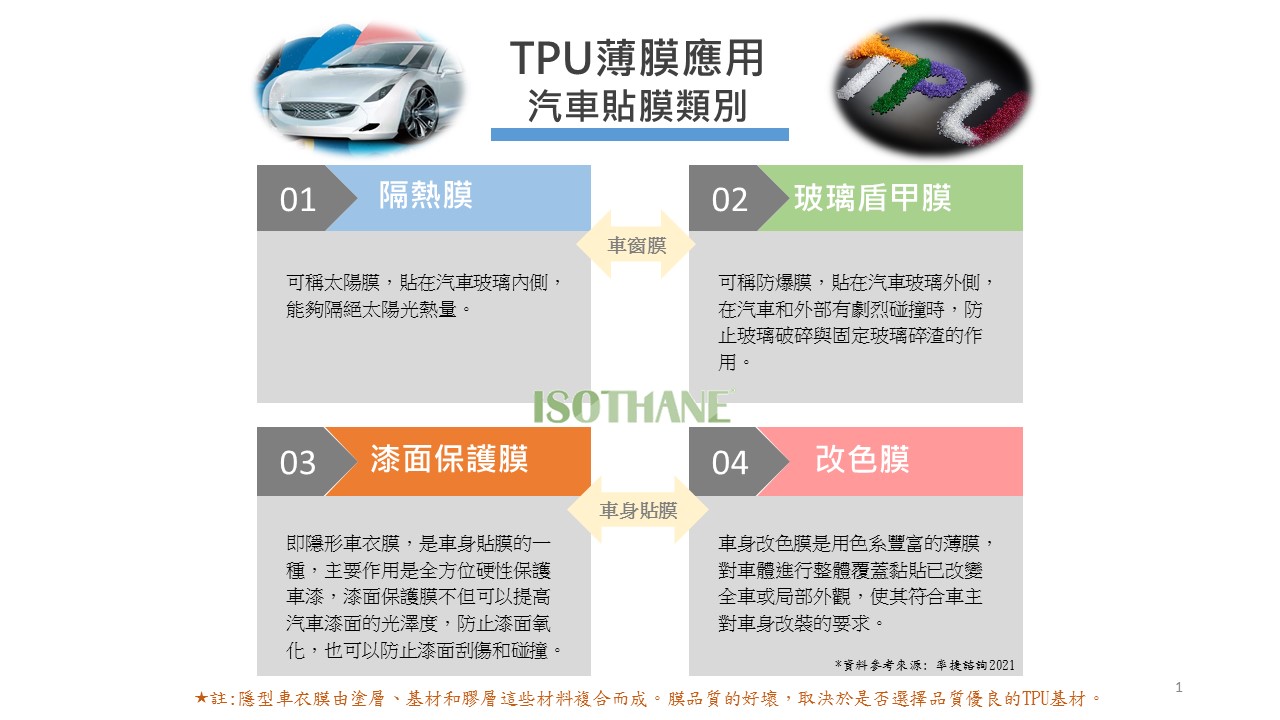

Car film can be divided into different types according to different needs. The most common classifications are heat insulation film, glass shield film, paint protection film and color changing film.

The first two belong to the window film, the latter two belong to the body film, and the main application fields of TPU are glass shield film and paint protection film.

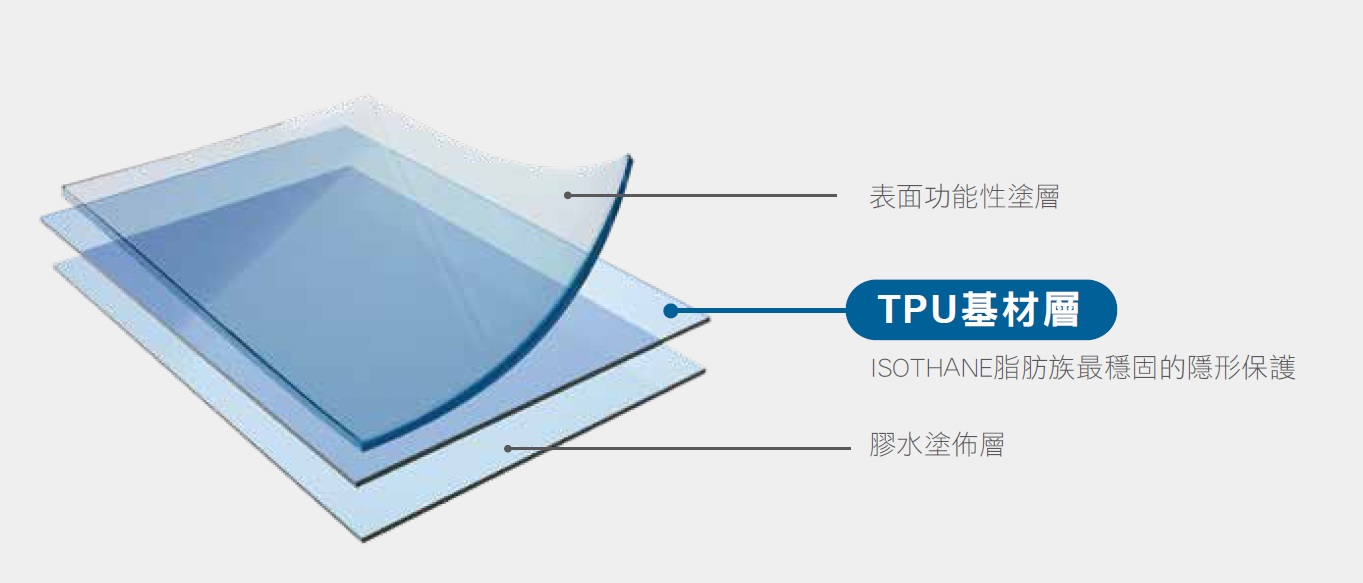

Early and low-end car coating films used PVC and PU as base materials. With the trend of environmental protection and the improvement of new materials, high-end car coating films prefer to use TPU materials with excellent UV resistance and non-yellowing aliphatic. The TPU invisible car cover is made of TPU base material layer, which is made by precision coating and protective surface functional coating and glue, and laminating the release film. Simply put, all invisible car cover films are composited from the materials of surface functional coating, TPU substrate layer and glue coating layer.

In the automotive field, more and more TPU films are used for paint protective film, anti-scratch protection, anti-chipping, etc. The automobile industry is developing in the direction of green environmental protection, light weight, comfort and safety. Polyurethane materials are gradually replacing some metals and traditional rubber and plastic parts. Today, the amount of polyurethane has become one of the important indicators to measure the quality of cars.

The future trend of green materials, towards the development of modification and composite technologyTPU material has excellent performance and a wide range of applications. It is the best choice for environmental protection materials in all walks of life. However, there are still some shortcomings in its own characteristics. In order to solve this problem, GRECO research and development team must To develop products suitable for customers in the way of modified TPU and composite TPU technology. For example: TPU is blended and modified with some polymer materials to become a special TPU composite material, which can improve the elasticity, wear resistance and impact resistance of other materials. Long fiber reinforced thermoplastic TPU composite material is a good example. Through composite technology, combining the advantages of two raw materials, it has high rigidity, good heat resistance, excellent dimensional stability, and wider applicability.

In the future, the composite technology and innovative modification technology of TPU and other materials will become an important development trend of global TPU technology and will become a high-performance and stable invisible protection in the environmentally friendly materials of the green supply chain.