Eco-products make life more energy efficient and make the world a better place to live.

Welcome to visit us at the following two trade shows:

1. Chinaplas 2024 - Booth No.: 1.2G74 1.2G74

Date: April 23-26, 2024

Location: National Exhibition and Convention Center (NECC), Hongqiao, Shanghai, PR China

2. NPE 2024 The Plastics Show - Booth No.: South Hall_S32094

Date: May 6-10, 2024

Location: Orange Country Convention Center, Orlando, Florida

This international certification is an important milestone in our commitment to environmental protection, which not only demonstrates GRECO's sustainable business mission, but also highlights our adherence to quality and environmental standards.

Bio TPU resin

Bio-TPU is a biomass source material and recyclable material, which can save energy, reduce carbon emissions, and provide excellent physical properties of the original chemical. It not only has excellent toughness, mechanical strength, wear resistance and solvent resistance, but it is also a sustainable resource that can replace petroleum fuels and organic chemistry.

GRECO’s Bio-TPU resin has been promoted for many years, and has been affirmed and developed by many well-known brands and manufacturers. It has been widely used in daily necessities, such as film materials for food packaging, waterproof and breathable sportswear, functional gloves, sports and leisure sneakers, low-temperature resistant snow goggle frames, bicycle spare parts, 3C laptop peripheral parts and life jackets, etc.

In the past, most of the materials relied on petroleum extraction. To reduce the harm to human and the earth, people start to pursue non-toxicity and back-end recycling. Thus, GRECO has developed ISOTHANE Bio-TPU resin with solvent-free and non-toxic, bringing more convenience and safety to life, and continues the green future of the earth.

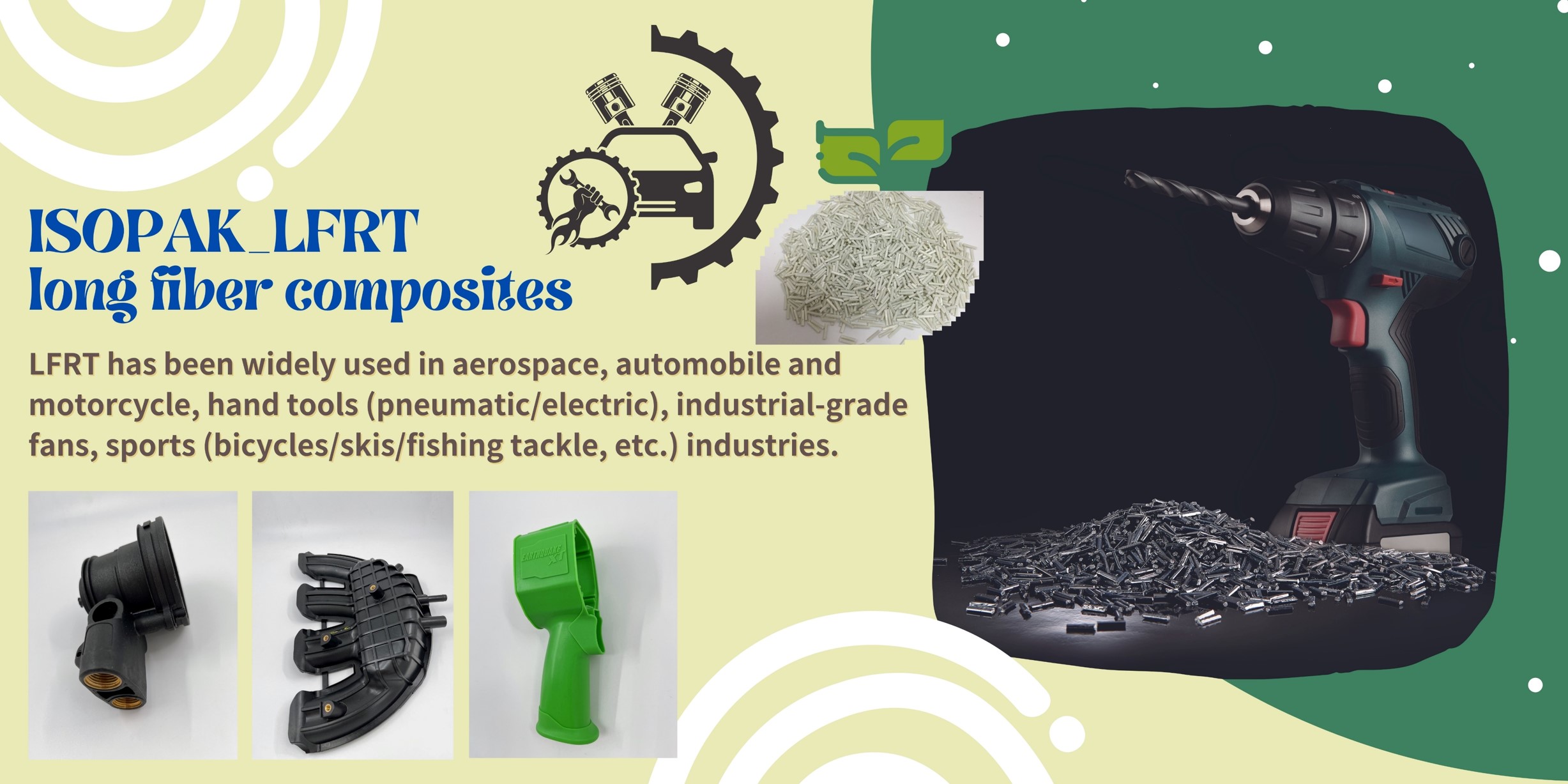

LFRT long fiber composite

LFRT has been widely used in aerospace, automobile and motorcycle, hand tools (pneumatic/electric), industrial-grade fans, sports (bicycles/skis/fishing tackle, etc.) industries. In terms of the application of automobile and motorcycle components, metal materials were preferred in the past for many industrial products due to their high strength and heat resistance, whereas they were not suitable for forming complex shapes. Instead, LFRT is not only similar to the performance of metal, but also has the advantages of excellent specific strength, rigidity, impact resistance, dimensional stability, temperature resistance, low warpage, creep resistance, low thermal expansion coefficient, etc., which makes it an optimal choice to replace metal.

ABS resins

GRECO has always been committed to the research and development of environmental-friendly products, with the concept of energy saving, carbon reduction, and recyclability, to achieve a better life.

If you are interested in our eco-friendly products, please feel free to contact us.

E-Mail: sales2@greco.com.tw

TEL:886-4-23587600

Contact: Mr. Duke Shih